About Us

In transportation, every detour, delay and downtime translates into cost. With global logistics networks expanding, AI in transportation has become the core of safety, efficiency, and sustainability. From autonomous fleet operations to predictive routing, artificial intelligence is now integrated in how people, goods, and data move – and how quickly they reach their destinations.

AI in transportation market is expected to cross $10.3 billion by the end of 2030, growing at an annual rate of over 12%. This momentum is backed by edge computing, IoT, and generative AI, enabling smarter decision-making across ports, fleets and public transit systems.

For logistics teams and startups, this is not just a trend, it’s an entirely new model for operations. Companies that are integrating AI into predictive maintenance, dispatch, and demand forecasting strategically are already witnessing 15-30% gains in the utilization of assets as well as measurable reduction in carbon emissions. Find out how logistics dashboards are unlocking real-time supply chain visibility and profitability in this detailed guide.

This article breaks down how AI is transforming transportation, where the highest ROI opportunities lie and how you can design an AI-ready infrastructure, even if you’re barely starting with a minimal tech stack.

Partner with AI experts to design, test, and scale your transportation software with measurable ROI.

Key Takeaways

Artificial Intelligence is redefining how transportation works, not with a single innovation but through optimization of every part of the network. From city-level traffic control to fleet operations, AI is enabling real-time decision-making that enhances cost-efficiency, safety, and sustainability.

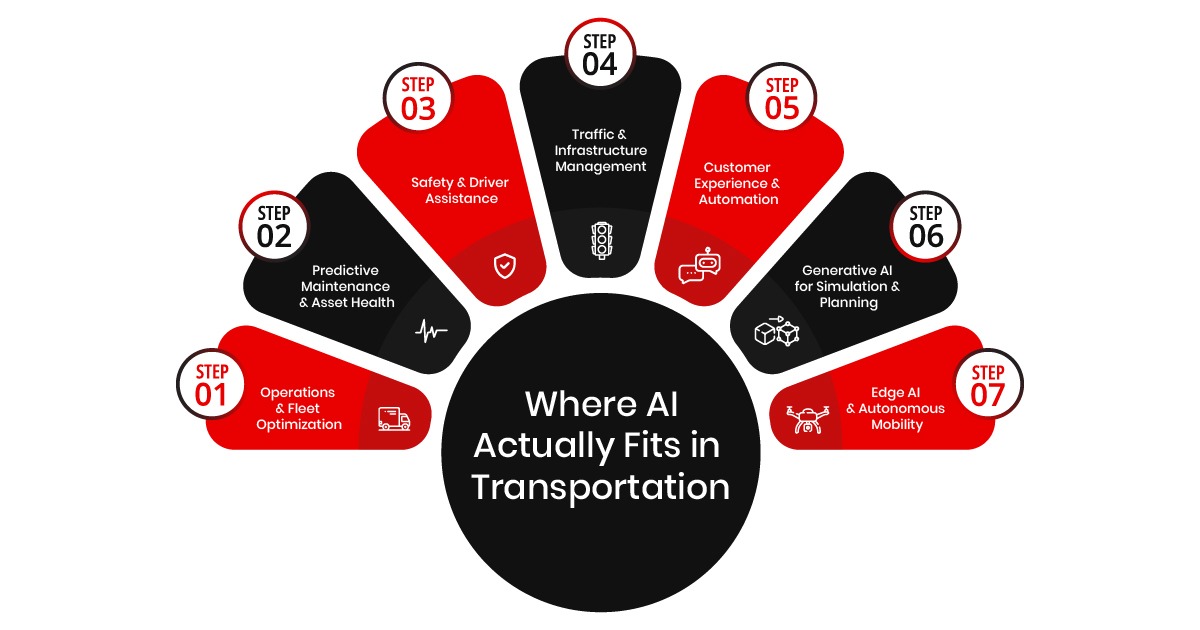

Here’s a thorough description of the core application areas of AI in transportation and logistics so you can understand how they’re contributing to the modern business models and operational transformations.

Operations and Fleet Optimization: AI-backed route optimization algorithms are designed to analyze live data from weather APIs, GPS, and traffic cameras to assist with reducing delivery times and fuel consumption.

Real-time dispatch that instantly reroutes vehicles on the basis of reported accidents or congestion can reduce fuel costs by 20% and increase delivery times by 30%. Commonly used tools for this purpose include. Dynamic ETA prediction, machine learning-based route planning and AI fleet management dashboards.

Predictive Maintenance and Asset Health Monitoring: machine learning models help with the detection of anomalies in temperature, engine vibration or break wear before the failure actually occurs. This can help reduce unplanned downtime by almost 40% and maximize the vehicle’s lifespan.

Methods like anomaly detection, sensor fusion and time-series analysis are used to perform this function.

Safety and Driver Assistance: computer vision systems also use AI to keep track of road conditions, identify fatigue and prevent any collisions. Advanced driver assistance systems (ADAS) such as pedestrian recognition, lane departure detection, AI dashcams and emergency braking algorithms are often used to alert drivers about any potential risks or threats. It helps reduce both accident rates and insurance claims.

Traffic and Infrastructure Management: city-level traffic signals, public transport schedules, and toll booths are all being increasingly controlled by AI. Adaptive traffic signal systems such as AI-backed traffic cameras, Edge AI for local signal control and predictive congestion models are often used for the purpose and help with ensuring a seamless flow of traffic, lower carbon emissions in urban centers and reduced congestion.

Customer Experience and Automation: AI enables chatbots for transport services, predictive ETAs and personalization in routing and ticketing. Using natural language processing (NLP) and generative AI for query handling in chatbots that are meant for logistics updates and ticketing queries can help maximize service satisfaction and customer retention.

Generative AI for Simulation and Planning: The latest innovation of AI in transportation is the use of generative models for stimulating logistics routes, infrastructure and maintenance schedules before deployment. Digital twin simulations help business planners and decision-makers evaluate the ‘what-if’ scenarios without any real-time disruption in the networks, allowing data-driven investment decisions and quicker pilot testing.

Edge AI and Autonomy: with most vehicles becoming sensor-rich, edge AI enables split-second decisions for safety and autonomous navigation. Self-driving delivery vans and AI-powered drones for last-mile logistics are helping reduce the human-error and maximizing delivery coverage in constrained areas.

AI isn’t just a single solution, it’s a full-feature stack of intelligent layers integrated across the multiple operations of transportation. From system-wide optimization to vehicle-level decision-making, AI in transportation is making an impact in every corner, be it big or small. Companies that are investing early in AI are setting themselves up for sustainability, scalable efficiency, and competitive edge.

While routing automation and predictive maintenance are an integral part of how AI is transforming transformation, they’ve become pretty mainstream in 2025. What’s really helping startups standout are the next-wave applications that combine sustainability with data-blends and intelligent automation in modern ways.

Here’s the list of emerging AI opportunities that smart logistics founders and leaders can adapt in order to succeed:

Digital Twins for Smarter Network Planning

Think of it: you’re capable of testing every delivery route, scheduling tweak, or infrastructure change virtually before it happens in the real world. That’s exactly what digital twins backed with AI can help you do.

Sustainability isn’t just about PR anymore, it’s become a competitive advantage. One of the finest benefits of AI in transportation is that these systems can now calculate both speed and distance not just by the speed but also through carbon footprints.

Insurance premiums are often volatile in logistics, but AI use in transportation is changing how they can be calculated.

A major roadblock of AI in logistics and transportation is data sharing. Companies do not want to compromise on their sensitive data related to drivers and routes but still take benefit of collaboration.

Generative AI in transportation and logistics isn’t limited to the chatbots only, it’s now proving power in simulating disruptions, predicting freight demand and planning resource allocation. For example, using ‘what-if’ simulations can help manage driver shortages, peak season loads, and port delays very effectively.

Speed matters the most in logistics. Edge AI, running models on IoT devices or vehicles directly, can help reduce the latency and maintain instant decision-making.

Traditional freight booking still faces empty miles and inefficiency. AI in transportation is helping with smart load-matching algorithms, optimizing those empty miles.

The opportunities for innovation are endless; they go beyond automation and are redefining how transportation ecosystems think and operate. Startups that are investing to explore generative AI, digital twins and sustainability-driven algorithms now are positioning themselves on top of competitors who are still only focusing towards basic analytics and optimization.

Let’s identify quick-win AI pilots tailored to your business goals.

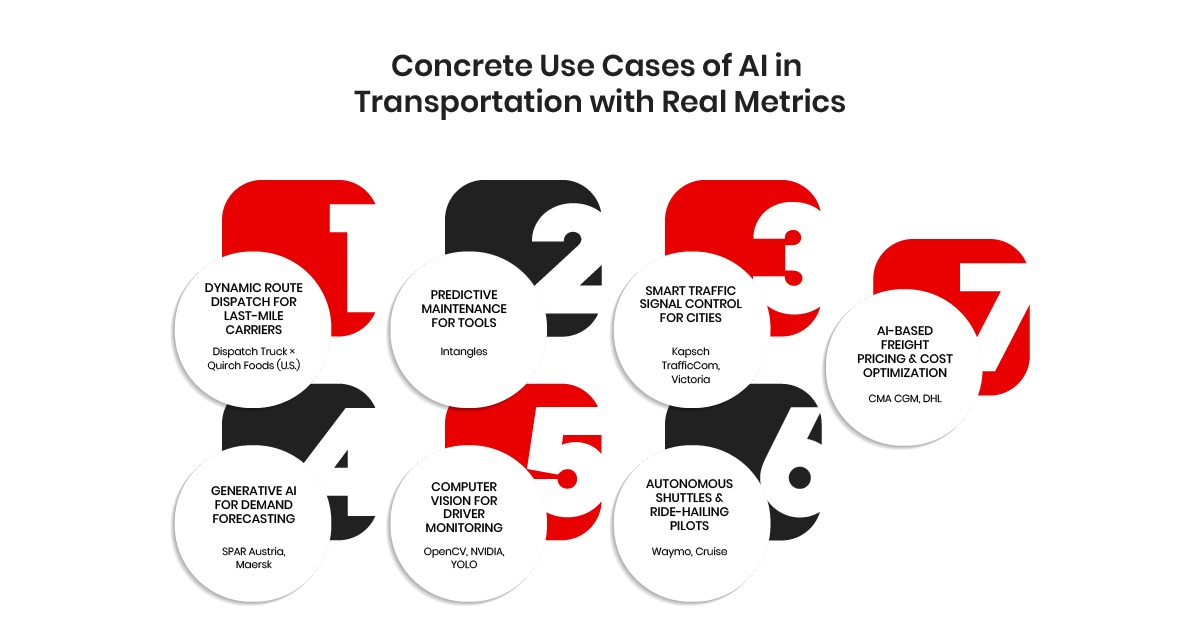

The impact of AI on transportation isn’t just theoretical anymore, it can be seen in real dashboards, KPIs and cost reports. Some of the most promising AI applications in transportation and logistics include:

KPI: fuel consumption per trip, average delivery time

Case Study: Dispatch Truck integrated a hybrid routing solution for Quirch Foods (U.S.). They use static route skeletons and dynamically adjust stops as deliveries happen. The integration led to faster delivery fulfillments and better route efficiency.

Impact: The Company claims an average 3 times better efficiency in fulfillment compared to traditional methods.

Tech Stack: mobile driver apps + cloud-based routing engine + real-time traffic and delivery windows integration.

KPI: downtime percentage, maintenance cost saved

Real-World Example: Intangles was facing a major issue around their waste-truck fleet. Integrating a predictive maintenance system helps them identify radiator clogging issues even before the failure so that they can be repaired timely. The system has graphic sensors that send alerts on the basis of temperature changes.

Impact: they report preventing an average 2 overheating breakdowns every month; saving thousands in towing and downtime and majorly reducing the reactive repairs.

Tech Stack: alert dashboards + telematics + IoT sensors + time-series anomaly detection models.

KPI: carbon dioxide emission reduction, travel-time reduction

Real-World Examples: Kapsch TrafficCom ran a pilot testing in Victoria, Spain. They deployed transit signal priority (TSP) systems so the buses could automatically receive green lights along busy routes.

Impact: It helped enhance the bus schedule adherence and cut-down wait times at the intersections on Line 5. While there’s no report published about the total quantitative gains yet, the initial outcomes show a seamless flow of traffic and reduced delays.

Tech Stack: vehicle detection + connected traffic signal controllers + priority logic + integration with existing traffic management systems.

KPI: load utilization rate and forecast accuracy

Real-World Example: SPAR Austria managed to enhance their demand forecasting by using a combination of Microsoft Azure with partner Paiqo. They leveraged market trends, historical sales and external factors to get an above 90% forecast accuracy.

Maersk also uses generative AI and simulation tools to forecast schedule loads, route congestion, and plan container handling.

Tech Stack: time-series forecasting + generative AI models (simulations) + cloud infrastructure + visualization tools.

KPI: driver alertness score and safety incidents prevented

Use Case: many fleets in the U.S. are piloting video-based fatigue detection and lane-departure monitoring using computer vision such as: OpenCV, NVIDIA, YOLO.

Impact: While the use of computers for onboard driver monitoring is showing incredible results, companies are often reluctant to share that publicly because of privacy. It sure is a technology worth experimenting with whether you’re a startup or an existing enterprise that aims to innovate.

KPI: regulatory compliance milestones and safety incidents per million miles

Real-World Example: Waymo and Cruise are top names in the ride-hail/autonomous shuttle industry. The Guardian reports a very low rate of incidents for Waymo’s AVs in operation regions, meaning the autonomous systems are working just fine.

There are multiple other small pilots happening in different areas for campus shuttles, etc. While this is worth investing in, regulatory frameworks often vary from place to place and there’s strong requirements for extensive insurance, remote human oversight and safety validation.

Tech Stack: deep learning perception models + LIDAR/radar/camera stacks + redundant safety systems + edge computing

KPI: profit margin per load, quote response time, pricing accuracy

Real-World Example: CMA CGM, a giant in shipping and logistics, recently signed a deal with Google to integrate AI tools to optimize their routes, handle container operations, and manage inventory, including better pricing and forecasting.

DHL is also using generative AI to plan routes and track shipments, etc. These tools often come along with cost and pricing optimization.

Impact: better cost forecasting, enhanced route selection (less idle time), and more accurate pricing under varying conditions.

Tech Stack: ML regression/forecasting + dynamic pricing engines + APIs for shippers/carriers + external data (fuel prices and traffic)

These real-world applications prove AI’s tangible business impact. But turning such use cases into scalable software solutions requires strategic planning; starting small, iterating fast, and measuring continuously.

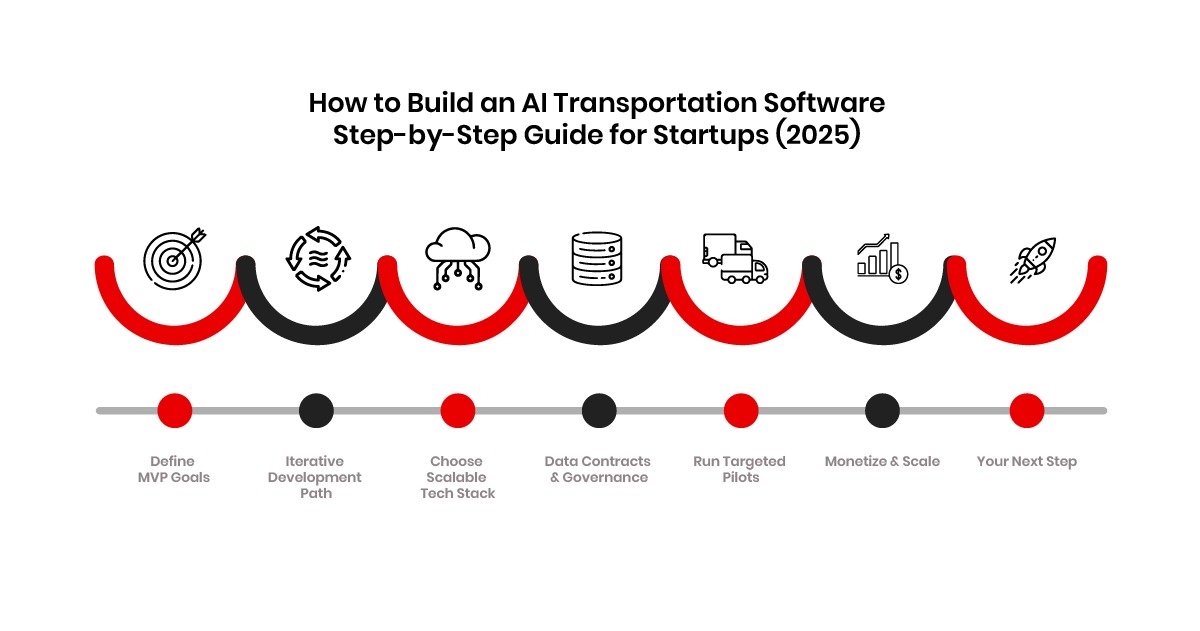

AI in transportation doesn’t begin with a massive neural network or a self-driving fleet, it starts with a data-driven, focused MVP. The goal is to validate value early, automate one process at a time, and build scalable layers over months, not years.

Below is a complete, practical roadmap designed for startups and logistics teams aiming to bring AI-driven efficiency into transportation operations:

The most successful AI transportation products start small, by tackling one high-ROI pain point like:

Your MVP should integrate three essential layers:

Avoid going all-in with complex AI pipelines early. A fast, incremental roadmap gives both early revenue traction and lower risk.

Fast path to AI maturity:

This staged approach balances cost, data maturity, and time-to-value, critical for startups seeking investment or pilot traction. If your AI use case revolves around fleet automation or a freight management system, check out how logistics apps use iterative scaling.

Your tech stack should allow for fast prototyping, low latency, and modular scaling.

Suggested stack:

Each tool aligns with the goal of fast iteration and traceable performance improvement. For startups comparing frameworks or platforms, here’s a deep dive into some of the best mobile app frameworks for cross-platform development.

Your data is your product. Define data contracts upfront, what each sensor sends, in what format, and how often.

A typical setup includes:

Pair this with a governance layer:

Frameworks like ITS America and ISO 26262 can help structure compliance for city or fleet pilots.

Instead of a big launch, deploy to a limited test environment — a fleet of 3–5 vehicles or one delivery corridor.

Track business KPIs from day one:

Use monitoring dashboards (Grafana, MLflow) to visualize improvement trends and validate the ROI story.

Once pilots deliver measurable gains, move toward productization:

Example growth timeline:

Building AI in transportation isn’t about scaling fast — it’s about getting something useful running fast and letting data prove its worth.

If you’re a startup or logistics business exploring AI in transportation, begin with a pilot use case that solves one clear operational bottleneck.

Define your KPIs, deploy a lean MVP, and gather real metrics, the rest will follow. You can also learn about logistics software development cost by reading our detailed guide and make decisions accordingly.

Our AI engineers and logistics experts can help you identify the right use case, build a lean MVP, and scale with measurable ROI.

| Challenge | Impact on Project | How to Avoid / Mitigation Strategy |

|---|---|---|

| Poor Data Quality & Labeling Errors | Leads to inaccurate predictions in routing, demand, or maintenance models. | Set clear data contracts early; use human-in-the-loop validation and automated labeling audits. |

| Ignoring Edge Cases (weather, GPS loss, driver habits) | Models fail in real-world conditions and underperform during peak hours. | Expand training datasets with synthetic or diverse inputs; simulate rare scenarios before deployment. |

| Model Drift Over Time | Accuracy declines as routes, demand, or traffic patterns change. | Use continuous model monitoring (EvidentlyAI, MLflow) and quarterly retraining with new data. |

| Over-Engineering Early MVPs | Slows down pilot delivery and delays ROI. | Start with rule-based automation, then evolve to hybrid and ML systems gradually. |

| Privacy & Compliance Issues | Violations of GDPR/CCPA with telematics and video data. | Apply data anonymization, restrict PII access, and follow ISO/ITS data-sharing standards. |

| Lack of Explainability & Transparency | Stakeholders and regulators distrust “black-box” models. | Use explainability tools (SHAP/LIME) and maintain full audit logs for every prediction. |

| Limited Edge Compatibility | AI inference runs too slow in real-time logistics operations. | Deploy edge inference engines (NVIDIA Jetson, AWS Inferentia) for latency-sensitive tasks. |

| Inconsistent Integration with Fleet Systems | Data silos between telematics, routing, and ERP tools reduce insight accuracy. | Adopt API-first architecture; standardize data exchange formats (JSON/CSV/Parquet). |

| Scaling from Pilot to Production | Models perform well in pilots but fail at scale due to infrastructure limits. | Use containerized MLOps pipelines and cloud-native scaling via Kubernetes or Vertex AI. |

| Lack of Clear KPIs and ROI Tracking | Difficult to prove business value to investors or fleet partners. | Define quantifiable KPIs (delivery time, cost per mile, downtime %) before pilot launch. |

Pro Tip: the fastest growing logistics startups focus on modular AI layers and data discipline, not the giant, all-in-one systems. Each pilot should be capable of validating one KPI, automate one process, and generate one measurable business outcome at a time.

A critical question that you’ll often come across as a founder or logistics team is ‘how do we measure whether AI in transportation is actually worth it?’

The answer is simple – AI isn’t a technology expense, it’s a strategic investment that multiplies over time through reduced downtime, operational efficiency, and enhanced decision-making. Calculating the ROI (return on investment) requires connecting technical metrics with financial outcomes.

You can start by defining baseline performance metrics that can realistically improve with the help of AI. The most common KPIs linked with ROI include:

| Metric | Pre-AI Baseline | Post-AI Target | Typical Improvement |

|---|---|---|---|

| Average delivery time | 60 mins | 50 mins | 15–20% faster |

| Fleet downtime | 10% | 7% | 30% reduction |

| Maintenance cost per vehicle | $800/month | $640/month | 20% savings |

| Fuel efficiency | 6.0 MPG | 6.6 MPG | 10% improvement |

| On-time deliveries | 85% | 95% | 10% gain |

Here’s a generic formula you can use to determine the ROI:

ROI (%) =Implementation Cost (Savings + New Revenue) – Implementation Cost×100

Once you’ve defined the KPIs, it becomes easy to translate improvements into dollar value. You can do that as follows:

Startups can often attain 20-25% reduction in the operational cost within 12-18 months of deploying an AI-powered logistics system.

To get an accurate ROI, include all major investment components:

On average, an AI transportation MVP costs $80K–$150K, but the payback period can be under 18 months for mid-sized logistics operators.

ROI grows non-linearly, the more data you collect, the smarter your models get.

A simple projection looks like this:

You don’t need massive datasets to see results, just a focused pilot, clean data, and measurable KPIs.

When executed right, AI in transportation transitions from a cost center to a profit multiplier within the first operational year.

AI is no longer an experimental edge in transportation, it’s the new operating system for how fleets move, optimize, and grow. From dynamic routing and predictive maintenance to carbon-aware logistics, AI transforms every mile into measurable intelligence.

But realizing that potential requires more than models, it demands a strategy, a scalable tech stack, and a reliable development partner who understands both logistics and machine learning. That’s where AppVerticals comes in.

As an experienced logistics software development company, AppVerticals helps startups and enterprises move from concept to deployment with confidence. Our team specializes in:

Whether you’re planning your first pilot or scaling to a national rollout, AppVerticals can help you build, integrate, and deploy AI solutions that drive real business impact.

Let’s turn your fleet data into decisions that move business forward.

Start your pilot today.

Discover how our team can help you transform your ideas into powerful Tech experiences.